Domas System has developed a cost efficient tub press-out system. This system is similar to existing tub press-out systems, but has some major improvements:

- Lifting is done by a spindle construction. This construction does not need a yearly check by an external company. Regular checks can be done by your own maintenance people

- Lifting is done by an electrical drive Atex and NON Atex, this is much more cost efficient then air driven systems from our competitors

- Lifting is done by an electrical drive Atex and NON Atex, this is less noise for the operators

- Press plate is almost flat on the top. In the rare case of leaking to the top side of the plate, this can be cleaned very easy

- User modifications are possible (connection to other machinery, control by peer)

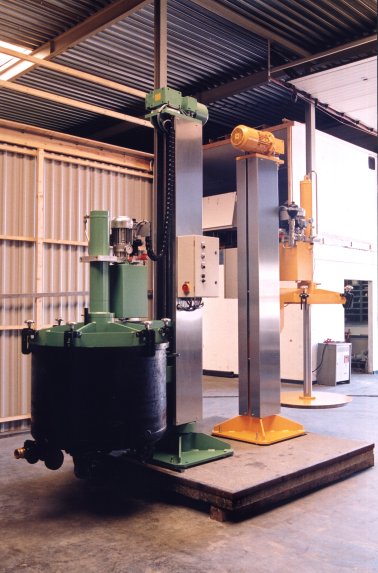

Press out unit- fixed column

This unit is used to press out containers. It is mainly used to empty containers above a three roller mill. It is also used to feed a dosing system.

Above a Buhler 3 roller mill

The press out unit communicates with the Buhler3 roller mill when product is needed.

Here are some of the options available:

- Column turnable with brakes or a stationary column

- With or without hydraulic accumulator

- Sealing by O-ring or bellows

- ATEX

- whatever you wish………